Robotic Fabrication of Sustainable Hybrid Formwork with Clay and Foam for Concrete Casting

Collaborating with Zhejiang University, 1DL published a paper on the development of a fabrication method for hybrid material sustainable formwork for serial concrete architectural components manufacturing. The paper was published at the 2020 annual Conference of the Ibero American Society of Digital Graphics International Conference (SiGraDi). This is an ongoing research, and the paper demonstrates the initial results.

Abstract

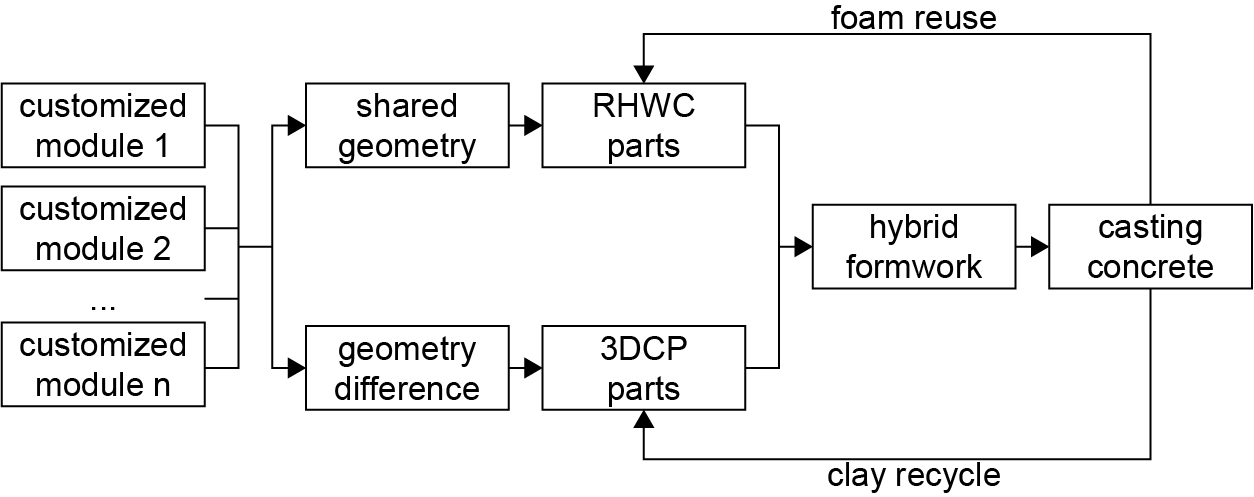

This research presents a hybrid formwork fabrication method utilizing additive manufacturing with clay on top of curved foam surfaces robotically fabricated with hot wire. The primary focus of this study is to develop a relatively efficient and highly sustainable formwork manufacturing method capable of producing geometrically complex modular concrete building components. The method leverages fluidity and recyclability of clay to produce uniquely shaped, free-form parts of the mold, and reduces overall production time by using foam for shared mold support/enclosure. A Calibration and tool path generating method based on computational modeling to integrate the two systems are also subsequently developed.

Click here to read the full paper.

Contact us for more information and collaboration: